Forest glass - Waldglas

The Tradition of Historical Green Glass Production in Bohemia

Green Forest Glass

The green color of forest glass is caused by ferrous oxide – FeO. The term forest glass (German Waldglass) is historical, as glassworks required charcoal to heat the glass furnaces. Since wood was abundant in forests, glassworks were often established in mountainous and forested areas near borders.

The glass industry flourished during the reign of Charles IV, who invited glassmakers from Italy and France. Local glassmakers had to rely on potash, which they extracted themselves from local wood.

Forest glass (German Waldglass) was typical of the late Middle Ages in Central and Northwest Europe and was produced until the 18th century, particularly in regions with abundant sand rich in quartz and wood used to produce potash. This type of glass was used for making vessels and later also stained glass.

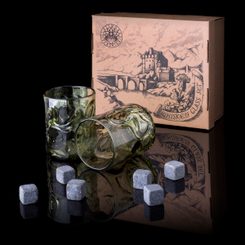

Dutch renaissance glass set in our offer.

Forest glass differs from "Roman glass" or Byzantine glass, which was primarily produced in the Mediterranean region.

In European areas under Roman control, Roman glass was made by adding soda (the mineral natron). This mixture of Na2CO3·10H2O with about 17% NaHCO3 and traces of sodium chloride and sulfates was sourced from deposits near Vesuvius, in Egypt (Wadi El Natrun), Chad, and other places.

After the fall of Rome around 450, glass production in Central and Western Europe declined, and glassworks focused on recycling old Roman glass.

Around 800, the Carolingian Empire expanded and competed with the Byzantine Empire in technological advances, increasing the demand for high-quality glass as a luxury item. Glassworks were predominantly established in mountainous areas of Central Europe.

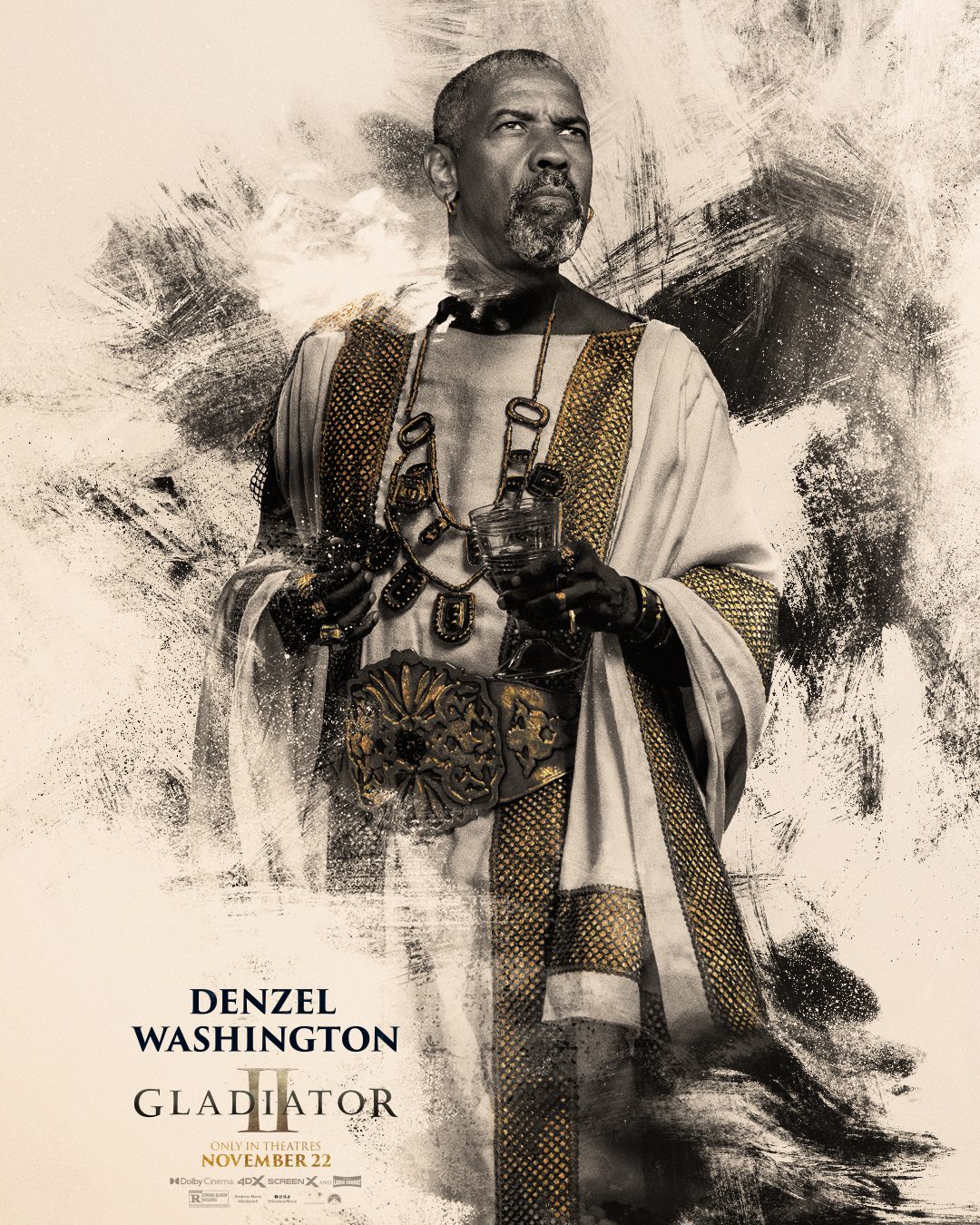

Denzel Washington with our gllass goblet - Gladiator II.

Glass Production

The main ingredient was silica sand with a high SiO2 content.

An alkaline flux was added to lower the melting temperature. For forest glass, potash (K2CO3) was typical, obtained from plants rich in sodium. In the Mediterranean, soda/natron (a mix of sodium salts) was used instead. Lime (calcium oxide, CaO) was also utilized as a flux.

Although potash lowered the melting temperature, it increased the glass's susceptibility to water corrosion. Therefore, stabilizing components were added to improve durability, such as calcium oxide (CaO), alumina (Al2O3), or magnesia (MgO), which could already be present in the sand.

Coloring agents – iron, copper, cobalt, manganese, tin, antimony, or lead were added.

For a long time, Venetian glassmakers kept their production methods secret, even forbidding craftsmen to leave the city. It was only in the 14th century that they discovered adding calcium oxide from shells, marble, or limestone to potash produced purer glass. This reduced the need for plant-derived potash, which often gave the glass varying color shades.

The history of glassmaking was described in the 12th century by Theophilus Presbyter and in the 16th century by Georgius Agricola, who also studied ore deposits in Jáchymov.

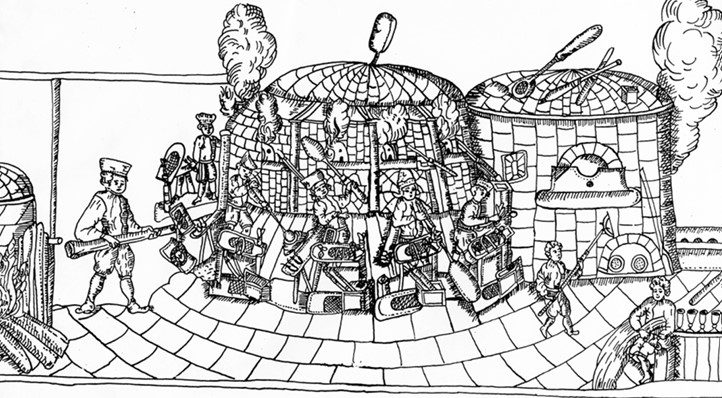

Drawing of a Glass Furnace Based on the Enamel Painting of a Humpen from 1727 This drawing is inspired by an enamel-painted humpen (a large decorative glass), reportedly now lost or in a private collection in London. The original painting was created by the glass painter Ignaz Preissler at the Zeilberg glassworks in Silesia.

How was forest glass produced?

Sand was usually collected from mountain streams and rivers.

Potash was often derived from beech wood. If the trees grew on calcareous soil, they contained more CaO. It is estimated that up to 200 kg of wood was needed to produce 1 kg of glass.

A mixture of ash and sand was heated at approximately 900 °C, a relatively low temperature. The heated material was then melted with fluxes in furnaces at around 1350 °C.

The appearance and construction of glass furnaces were documented in 1380 in Bohemia. The glassworks were separate buildings with multiple furnaces, each with specific temperature controls, all enclosed in a wooden structure. Glassworks were believed to operate for 40 weeks a year.

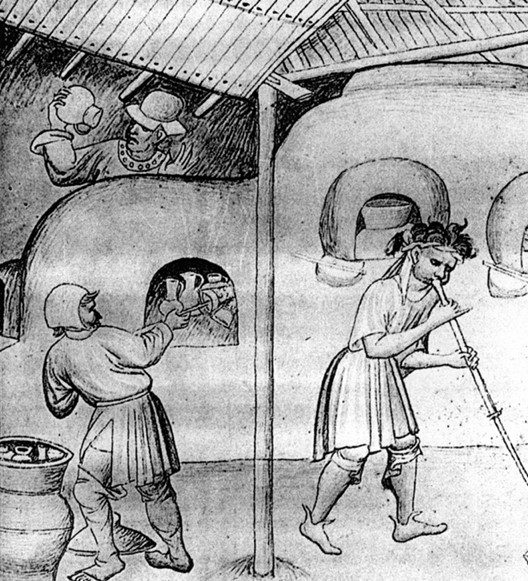

Medieval Glass Furnace in an Illumination of the Travels of Sir John Mandeville. Bohemia, circa 1410–1420. British Library, London. An illustration depicting the operation of a medieval glassworks. A detail of the lower part of the illumination shows a melting furnace and a cooling oven. On the left, a glassmaking assistant places finished products into the cooling oven.

Our Glass in Films and Series

Our company has been selling glass for many years. In addition to domestic customers, our products have found their way into renowned galleries, series, and films.

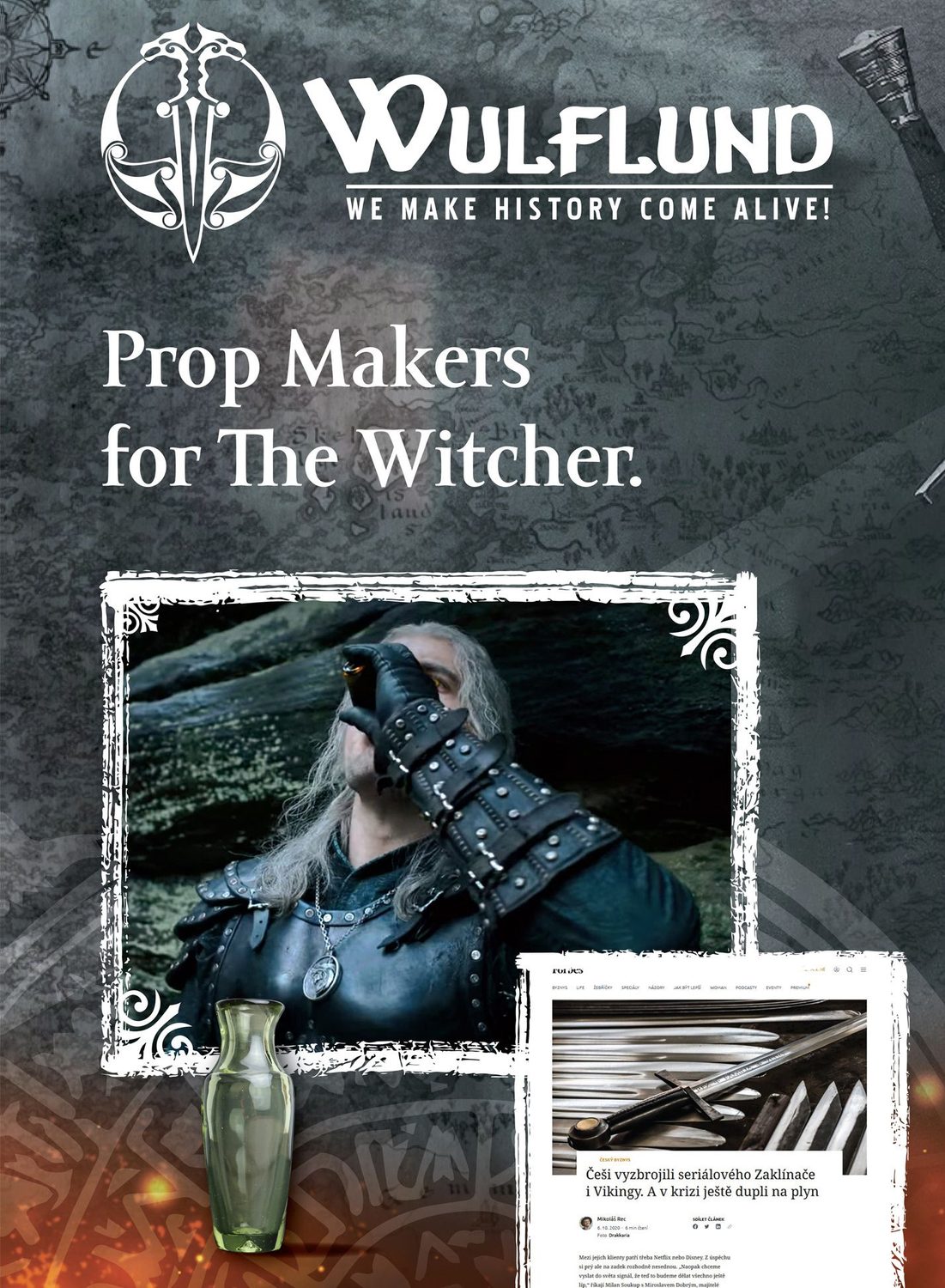

- The Witcher (Netflix)

- Gladiator II

- Vikings

We equipped Geralt with glass flasks from which he drank magical potions.

Historical glass supplied by Wulflund - The Witcher and Vikings Tv Series. Read more about our collaboration with Hollywood film productions.

Related products

And what to read next?

High-carbon carbon spring steel 54SiCr6

What is behind the success of Czech knives and swords worldwide? In addition to craftsmanship, we also owe it to high-quality spring steel.